Time Study

Definition of Time Study:

Time study tools:

· A stop watch

· Time study format

· One pen or pencil

How to conduct Time Study?

Step 1: Preparation

Step 2: Time capturing

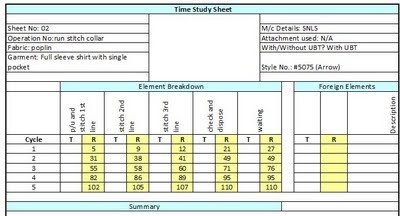

Table -1

Step 3: Calculation of Basic time

Table-2

Step 4: Calculation of Standard time

To convert basic time to normal you have to multiply it with operator performance rating. Here for example, rating has been considered as 100%. Now add allowances for machine allowances, fatigue and personal needs etc. Add machine allowance only to those elements where machine is running and fatigue and personal needs to all elements (approx 20%). Now we got standard time for each element in seconds. Sum up all elemental time and convert seconds into minutes. This is standard minutes Value or SMV.

Time study is a method of measuring work for recording the times of performing a certain specific task or its elements carried out under specified conditions. An operator does same operation (task) throughout the day. Time study help to define how much time is necessary for an operator to carry out the task at a defined rate of performance.

Time study tools:

· A stop watch

· Time study format

· One pen or pencil

How to conduct Time Study?

An operation cycle consists of material handling, positioning and aligning parts, sewing, trimming threads and tying and untying a bundle. So in the time study format, divide whole task into various elements according to the motion sequences of the operation. For example, in operation ‘collar run stitch’, task elements may be i) pick up panel to sew first seam, ii) turn collar to sew second seam, iii) turn collar to sew third seam iv) check work and dispose and v) waiting for next pieces.

Step 1: Preparation

- Ready with stationeries like time study format, stop watch (digital one) and pencil

- Select one operation for Time study

- Tell the operator that you are going measure time he/she taking to do the job.

- Observe the operation carefully and break down operation into elements.

- Fill the basic information in the time study format. Like machine category, guide or attachment used.

Step 2: Time capturing

Now measure the time taken for completing each elements of the operation cycle by the operator. Time should be captured in seconds. Similarly, capture element timing for consecutive 5 operation cycles. During data capturing only note down reading (see following table-1) of the stop watch and later calculate element timing. If you found any abnormal time in any elements record time during time study and later discard that reading. Or you capture time for one more cycle. Abnormal time may be occurred due to bobbin change, thread break, power cut or quality issues.

Table -1

Step 3: Calculation of Basic time

From the Reading (R) calculate time taken for each element for all five cycles just by deducting previous Reading from elemental reading. Sum up times of five cycles for each element. Note, if you discard any reading than in that case no. of cycles will be four. Calculate average element times. This average time is called basic time. (in the following table-2 it is noted as average time)

Table-2

Step 4: Calculation of Standard time

To convert basic time to normal you have to multiply it with operator performance rating. Here for example, rating has been considered as 100%. Now add allowances for machine allowances, fatigue and personal needs etc. Add machine allowance only to those elements where machine is running and fatigue and personal needs to all elements (approx 20%). Now we got standard time for each element in seconds. Sum up all elemental time and convert seconds into minutes. This is standard minutes Value or SMV.

No comments